Presentation and competitive advantages of a heating glass solution

Share this page

This article was written in collaboration with Christian BALLAY, director of the independent engineering company SYSELIA (specialising in active glazing: heated glass, dynamic solar glass, opacifying glass, etc.), one of whose members is Pierre GLORIEUX, the designer of the patented heated glass – IQ Glass.

How does a heated glass work?

The general principle is almost always the same, since it consists of heating a resistor that emits heat.

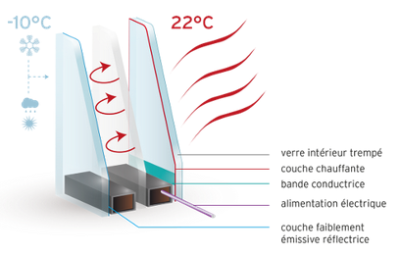

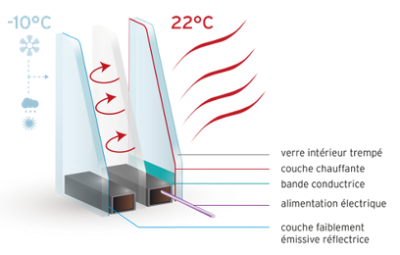

Heated glass is usually double glazing (see diagram), very similar in appearance to conventional double glazing. A transparent conductive metal oxide layer covers the inner wall of one of the glasses (inner glass in the case of the diagram). On either side of this layer are 2 electrodes allowing its electrical supply. When a current is applied, the conductive layer gives off heat through the Joule effect (dissipation of electrical energy in the form of heat energy), which is transmitted to the interior of the room. To limit energy loss, the outer pane is covered with a low-emission reflective coating.

@Heated glazing Calorglass

For which applications is the heated glass suited the best?

There are numerous potential applications. It may concern premisses:

- with spaces and volumes that require de-icing. This is the case, for example, of verandas, glass roofs, snow removal surfaces, aircraft windows, etc.

- where condensation is significant and demisting is required: spa areas, swimming pools, sports halls, glass partitions in bathrooms, etc.

- with non-standard glazing dimensions in order to reconcile the provision of light and the limitation of the «cold wall effect» which is amplified by the glazed surface (museums, institutional buildings, luxury hotels, etc.).

- where space constraints are important (boats, barges, mobile homes, etc.) and every cm counts.

Although it requires specific integration, it can be adapted to most window frames, sashes, sliding or folding windows, glass facades. Projects exist for entrance doors and glass partitions. The heated glazing can be integrated indiscriminately into aluminium, PVC, metal or wooden profiles.

The most common power supply is 230V.

How much power? For what energy impact? For what function?

The glazing must be sized by a specialist. A thermal study will make it possible to simulate and understand the functioning of the glazing in its final environment and thus to evaluate the energy impact on it. Intelligent heating management is essential to avoid over-consumption of energy. In the case of heated glazing, it is particularly important to ensure that the exterior is not heated, as is unfortunately all too often the case.

In terms of management, standard, open solutions will be preferred to specific solutions.

Power requirements and sizing for a main heating system in a very well insulated house: an average of 20% of the room surface should be in heated glass surface. For each project, this data must be defined during the studies.

Advantages and disadvantages of the heated glazing

Advantages of the smart heated glazing (depending on the manufacturer):

- Heating invisible to the naked eye. Appearance of traditional glazing. Space saving by removing all or part of the radiators.

- Suitable for all glazing formats and materials (wood, plastic, aluminium).

- Limiting the «cold wall» effect of glazing.

- Even distribution of heat over the entire pane.

- Elimination of condensation on windows and bay windows for total visual comfort.

- Very good responsiveness in terms of temperature rise.

- Maintenance-free heating system.

- Can be combined with other technical functions (blackout glass, dynamic solar glass, safety glass, etc.).

- Suitable for new build and renovation.

Constraints – Disadvantages of heated glazings:

- High energy consumption between 200 and 500W/m² (ideally associate to renewable energy source). 250 to 400w/m² for main heating source (source Saint Gobain Eglas).

- Theoretical efficiency: 3m² of glazing heats about 25m² of inner surface, that is 8m² heated by 1m² of glazing.

- Can hardly replace a whole heating system of a dwelling. The effectiveness depends on the rooms concerned.

- Safety: privilege a quality solution so that the electrical insulation between the electrical heating element (220V) and the users is complete.

- The principle of the radiation is to be able to reach all the cold areas from the heat emitter. So be careful that the concerned glazing can reach all areas to obtain a good thermal comfort. Learn more about the infrared radiation.

- More suited to new constructions than renovations.

- Still very high price.

- Unknown longevity. A priori limited risk of failure.

Average power consumption

Depending on the application and the available glazing surface, the power of the glazing to be used (averaged data) is, according to the manufacturers:

- from 50 to 100 W/m2 for an anti-condensation application,

- from 100 to 250 W/m2 for auxiliary heating,

- from 250 to 500 W/m2 for main heating

- from 350 to 700 W/m2 for a snow removal function (glazed roof).

Constraints – Disadvantages of heated glazing:

- Replaces all or part of a home’s heating system. Efficiency depends on the rooms involved.

- Safety: choose a quality solution that avoids accidental contact with the electric heating layer (230v) in the event of breakage of the outer pane. It is strongly recommended to choose certified glazing that meets current standards, particularly electrical standards.

- The definition and implementation of a heating glass project requires multidisciplinary skills (thermal, electrical, control, integration of the heating glass and installation of the joinery, etc.).

- The nature of the end-user’s needs must be clearly defined during the design phase, with regard to the possible functionalities (anti-condensation, snow removal, supplementary heating, etc.)

- Anticipate the routing of the cables required for the power supply and the control of the glazing.

- Price still high but becoming competitive as sales volumes increase and technology improves.

Price of heated glazing

This technology targets residential projects where maximum comfort is sought and projects adapted to the functionalities offered by heated glazing: anti-condensation for swimming pools, elimination of cold walls in heavily glazed spaces, snow removal from glazed roofs, etc. They are designed to be combined with all types of joinery.

The price excluding VAT (supply) and excluding installation is in the order of £500 to £700 per m².

Manufacturers of heated glass

EUROPEAN TOUGHENED GLASS (UK) LTD

With its four production sites European Glass has built up an outstanding reputation over the past 25 years for the rapid delivery of quality finished products.

The equipment used is state of the art. Made only in Europe, which allows integrators to provide the best quality even to their most demanding customers.

With one of the largest tempering furnaces in the world, European Glass can offer large-scale heated glass.

European glass group specialist manufacturer of heated glazing – Industry Leaders in

High End Glass Processing

SAINT GOBAIN GLASS (FRANCE)

Saint-Gobain has developed a new generation of EGLAS heated glass. They are aimed at applications such as demisting, supplementary or main heating, de-icing or snow removal. The heating power and the direction of heat propagation are adapted to the application.

Example of combinations that make up a heated window:

- External face SGG PLANITHERM XN whose purpose is to provide good thermal insulation from the outside.

- Heated glazing VITRAGE SGG EGLAS

- Laminated glass to ensure total electrical protection for users. Note that in the event of an impact on the glazing, it remains protected by laminated glass which also provides electrical insulation. The layer under electrical tension remains inaccessible.

The new version of EGLAS has a specially treated conductive layer that allows each pane to be connected directly to the mains, like a conventional electric heater.

eglas @ St Gobain

HTG (POLAND, SWITZERLAND)

Polish manufacturer of technical glazing (safety, fireproof, architectural, ballistic, etc.) including heated glass.

PRELCO (CANADA)

Prelco is a specialist in the manufacture of complex and innovative glass solutions. With 6 plants located in North America (650 employees), the Prelco Group is a world leader in value-added glass manufacturing.

Hotel Hilton Prelco Canada

GROUPE RIOU GLASS (FRANCE)

The French industrial group RIOU GLASS (18 factories in France) is, among others, the manufacturer of the heated glass Calorglass®. This manufacturer was awarded the innovation prize at the 2015 Paris trade fair. The principle is standard for heated glass: an invisible layer of metallic microparticles is deposited on the inner surface of the glass. The coating thus becomes a heating resistor. The radiation is at low temperature (up to 45°C). The solution is coupled with innovative home automation systems.

Various applications are possible for the residential sector (verandas, fixed or sliding windows, windows, French windows) and the tertiary sector (café terraces, office partitions, etc.).

heated glass Calorglass

Design companies for heated glazing

EUCG (France)

EUCG is the designer of the “Plug & Play” heated glass control solution bearing the same name (10 years of research to develop the process). The EUCG does not require any special skills in terms of installation and integration. The very active EUCG has filed several patents in recent years.

The EUCG system consists of modular elements. Source EUCG.

SYSELIA (FRANCE)

SYSELIA is positioned as an engineering service for building professionals wishing to implement active glass solutions (heated, dynamic, obscuring, luminous…..).

SYSELIA offers consulting, project management and design missions in this field.

Through its team members and the projects they have carried out all over the world, SYSELIA can put forward a unique experience of more than thirty years in the field of heated glass.

Within the framework of its R&D activity on heated glazing, SYSELIA has developed a module allowing the thermal behaviour of this glazing to be reproduced under TRNSYS (Dynamic Energy Simulation software for buildings and systems).

Partner of the SBA (Smart Buildings Alliance) for several years, SYSELIA is committed to implementing reliable, long-lasting, scalable control solutions, open to other building equipment (thermostat, existing heating, etc.) and offering a real manufacturer’s guarantee.

Active glazing engineering: #engineering #glazing #glass #active #heating #solar #dynamic #opacifying #luminous

VITRUM GLASS (FRANCE)

VitrumGlass is a design and project management office specialising in heated glazing and all types of intelligent glazing (opaque, dynamic, chromatic, etc.). The company carries out a thermal and electrical study, commits itself to a heating result that allows the end customer to be assured that the heated glazing will be the only heating system in the building. VitrumGlass can supply the joinery or offer the joiner machining plans for the integration of the intelligent glass in the frames. VitrumGlass proposes the best control system adapted to the customer’s needs and provides an electrical cabinet dedicated to the environment, which allows VitrumGlass to guarantee the glazing and the electrical installation for ten years.

Vitrum Glass is the designer of the Smart in Glass® solution for Plug & Play integration and intelligent control of heated glass and all the technological glass in its range (opaque, solar migration, OLED, etc.). The surface temperature is between 20 and 40°C, even at very low outside temperatures. Vitrum Glass specialises in the design, installation and management of high-end intelligent glass.

Example of a Duplex in Paris with heated glazing VITRUM GLASS

Learn more about innovative heating

Expert file: How to choose an insulator taking into account all the parameters (performance, environment, installation, etc.)?

Expert file: How to effectively filter indoor air?

EN-FOX5