Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 982

Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 982

Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 982

Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 984

Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 984

Warning: Trying to access array offset on value of type bool in /var/www/foxof.com/wp-content/plugins/all-in-one-schemaorg-rich-snippets/functions.php on line 984

Home / Smart Glazing / Should you install a self-cleaning glass? (español – français)

The self-cleaning glass that captures the UV rays to break down dirt

Share this page

Principle of a self-cleaning glass

The self-cleaning glass is made of an invisible coating that makes exterior glass maintenance easier.

The principle that is the most used by industry

The coating is composed of anhydride or titanium dioxide and silica. The purpose of these materials is twofold: to render the glass smoother in order to create a hydrophilic effect and to cause a chemical reaction (photocatalysis) with the UV from sunlight.

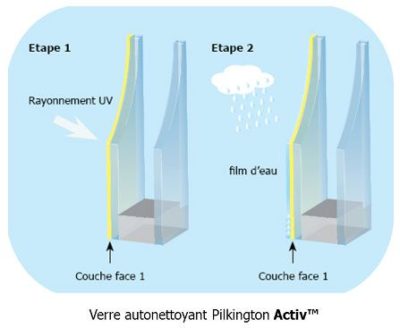

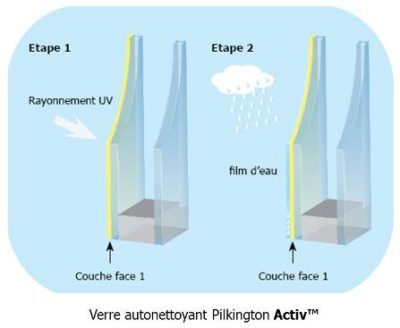

When the UV rays pass through the glass, the catalyst of the self-cleaning coating “oxidise” the organic compounds. Clearly, the dust and organic dirt that have accumulated on the external surface of the glass are automatically “decomposed”. Then when it rains, the residues are washed, rinsed and evacuated. The glass is clean thanks to self-cleaning, virtually stain free.

The hydrophilic effect occurs because the drops aggregate to form a film which then will flow along the glass by gravity. So there is no more evaporation, therefore no more traces.

Advantages of the self-cleaning process

- Save a significant amount on building maintenance, especially for the glazings situated at height, in areas complex to reach (office buildings, swimming pools, etc.) or even subject to heavy pollution (industrial area, urban area, etc.). The cleaning time is strongly reduced.

- The quality of natural lighting, the aesthetic and the visibility are greatly improved for the users of the building or the housing. The vision is clearer in the rain thanks to the hydrophilic function. Reduction of external condensation. So we limit the consumption in terms of artificial lighting.

- It works on all types of glazings (vertical, ceiling, sloping, veranda…) and on almost all types of technical glass (tempered, laminated, double glazing, solar and thermal protection, tinted, etc). This combination with other function allows the customer to benefit from major ecological support systems (tax credit, premium energy, etc.).

- This is a real gain from an ecological point of vue: less use of harmful detergents for the environment (provided that the solution has no impact on the environment in its constitution).

- The price of the extra cost of a glass with self-cleaning function is around 15 to 25% of the original glass price.

Current disadvantages of the self-cleaning process

- Works perfectly, including cloudy days, since at least 50 to 70% of UV rays passes through the clouds (depending on the nature of the clouds and their altitude). However, the principle can cause problems in world’s areas where it doesn’t rain too much.

- The glass must always receive natural light so that the process operates.

- The self-cleaning process described above degrades only the dirt of organic origin, not the one of mineral origin. So you need to rinse the glass with water without detergent from time to time, if it doesn’t rain enough. Technical progress on photocatalysis settling this problem is underway.

- The method is not intended for a manual application (such as a gel or coating), the highly technical treatment must be performed at the factory. It is therefore necessary to choose your glazings in a glass manufacturer who masters this process.

Not to be confused with the hydrophobic protective coatings!

In another field of application, there are coatings to be applied to glass surfaces with high traffic or heavy use. That’s the case of glass doors and showers, glass handrails, glass counters or vehicle windshields (cars, busses, trains, subways). These silicon based coatings are solidified to fill microporosities of the glass and render it hydrophobic. They repel water, limite scratches, fingerprints and the penetration of graffitis.

neat-prelco self cleaning glass

Self-cleaning glass solutions and manufacturers

SAINT GOBAIN’s SGG BIOCLEAN

This coating is applied to all glasses manufactured by Saint Gobain, for commercial buildings as well as for residential. The light transmission is particularly good (up to 80%) the film applied being the less reflective and coloured as possible.

PILKINGTON

The world leader glassmaker Pilkington offers a self-cleaning glass Activ® with pyrolytic layer for a reduced maintenance glazing. This feature is combined with other special glasses of the manufacturer (solar control, thermal and acoustic insulation, security, decoration). Pilkington highlights the excellent durability of its process and has a specific range where the visibility is important with a clear self-cleaning glass for stadiums or airports. The light transmission is up to 85%.

NEAT from PRELCO

Neat® manufactured by the Canadian company PRELCO is a hydrophilic protective coating. It is sustainable because it does not require any maintenance nor reactivation over time. It is applied on the external façade, via a process patented by the manufacturer on the main types of technical glasses (thermal insulators, opacifier, etc.). The manufacturer announces a better natural light transmission (less reflection) than the competition.

FOX18